Turnkey Systems from ELCON Technologies

ELCON Technologies is a UL508 and UL698 certified manufacturing facility. We also are certified for cUL and CSA.

At ELCON Technologies, we offer a unique combination of automation, power, and turnkey services, setting us apart from competing companies since most only specialize in one or two of these areas. We’re also not a repetitive manufacturer, as all the equipment we provide is customized and made to order so that it fits the unique needs of our clients.

When you work with us for turnkey automation, know that you’re gaining access to a team of industry experts dedicated to supplying the best systems possible. Our manufacturing facility is UL508 and UL698 certified, and we are also certified for cUL and CSA.

About Our Approach to Turnkey Automation Systems

Since 1988, we have been supplying manufacturers, industrial facilities, and municipalities with high-quality turnkey systems that streamline their operations and improve automation. For our systems, we:

- Design and build equipment using both standardized components and customized, specially designed parts to meet application needs

- Can meet key needs for both automation and power, setting us apart from the competition, as most automation companies don’t cover medium voltage power needs

- Use equipment from prominent manufacturers, like ABB, Eaton, Siemens, Toshiba, Honeywell, and Rockwell Automation just to name a few, to ensure we can offer only the best of the best

- Handle turnkey assembly automation projects from start to finish, with team members dedicated to designing, building, inspecting, and installing your equipment on-site

- Also offer services for fixing, upgrading, and maintaining existing electrical and automation systems, being able to provide tailored technological solutions that improve efficiency in sectors like manufacturing, energy, water treatment, and more

- Are always forward thinking when it comes to technology, such as being early adopters of efficient platforms like Ignition

- Provide remote service capability and can monitor and fix systems remotely via secure VPN connections, minimizing the need for on-site work

- Pride ourselves on our 24-hour response times to customer inquiries and issues, and we have multiple technicians available during weather events

Get In Touch

Reach out using the form below or call us at 412-822-8250.

Companies We’re an Ideal Partner For

- General industry, including automated bagging and production monitoring

- Midsize companies without large internal staff

- Organizations requiring automation services, national organizations for electrical power needs

- Steel plants and manufacturing facilities

- Water and wastewater treatment plants

For any of these businesses, we help to:

- Address equipment failure response and maintenance

- Enable environmental compliance and reporting

- Maximize productivity with existing equipment

- Minimize waste and improve consistency

- Promote energy efficiency and cost reduction

Examples of Our Turnkey Automation Solution Projects

Project 1: PWSA Ortho Phosphate Injection

We completed this turnkey factory automation project in quarter two of 2019. Our work included the following:

- Stand-alone ORTHO injection control at several water distribution sites, using Rockwell Data Historian supply and configuration

- SCADA sub-contractor

- SCADA scope included copper and fiber – the customer provided infrastructure and ELCON furnished network equipment, with new SCADA RTU’s integrated into existing SCADA level 2

- Stand-alone OIT’s

- Human machine interface software

- RSLogix5000 software

- Compact Logix processors

- Dedicated network homeruns to main IT distribution center

- UL 508A design-build control panels

- Capacitive and ultra-sonic level instruments

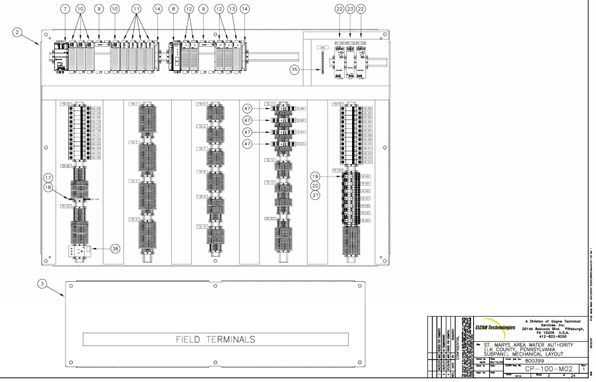

Project 2: St Marys WTP

We completed this turnkey automation project in quarter two of 2020. Our work included the following:

- Prime contractor

- Complete SCADA rehabilitation

- Redundant level 2 system

- Stand-alone HMI’s

- Human machine interface software

- RSLogix5000 software

- 3 compact Logix

- Remote site integration via ISP

- UL 508A design-build control panel

Project 3: Connellsville WWTP

We provided this turnkey automation solution in quarter four of 2021. Our work included the following:

- Complete WWTP rehabilitation including new SBR, headworks controls and motor drive systems, and two remote pump stations

- SCADA sub-contractor

- SCADA scope included copper and fiber and ISP to remote sites

- 5 compact Logix PLC

- Ethernet control of VFDs

- Redundant level 2 system

- Edge of network stand-alone HMI’s

- Human machine interface software

- RSLogix5000 software

- CompactLogix Ethernet remote input/output systems

- Ethernet communications networks

- UL 508A design-build control panels

- Flow, level, pressure, and analytical instrumentation supply and integration

Project 4: Rochester WWTP

We completed this turnkey system project in quarter two of 2023. Our work included the following:

- Complete WWTP rehabilitation including new extended aeration, headworks controls, RAS/WAS, and two remote pump stations, Cl system integration

- SCADA sub-contractor

- SCADA scope included copper and fiber and ISP to remote sites

- 5 compact Logix PLC

- Hardwired control of VFDs

- Redundant server-client level 2 VM

- Human machine interface software

- RSLogix5000 software

- CompactLogix Ethernet remote input/output systems

- Rockwell Stratix fiber ring

- UL 508A design-build control panels

- Flow, level, pressure, and analytical instrumentation supply and integration

Project 5: New Castle WWTP

We completed this turnkey factory automation project in quarter one of 2024. Our work included the following:

- Complete WWTP rehabilitation including new extended aeration, headworks controls, RAS/WAS, Cl system integration, renewable gas turbines, plant water system, bar screen integration, clarifier integration

- SCADA sub-contractor

- SCADA scope included copper and fiber

- Hardwired and Ethernet control of VFDs

- Redundant level 2 system

- Edge of network stand-alone HMI’s

- Human machine interface software

- RSLogix5000 software

- Redundant control Logix with CLX remote I/O

- Hub and spoke redundant network

- UL 508A design-build control panels

- Flow, level, pressure, and analytical instrumentation supply and integration

WE PROUDLY WORK WITH

Contact ELCON Technologies for Reliable Turnkey Automation Systems

If you’re searching for turnkey assembly automation solutions from an industry-leading manufacturer, ELCON Technologies is ready to partner with you. Reach out to our team today and we can discuss your project in detail.